BY MID-2013, natural gas-fueled tractors are expected to account for at least a quarter of the power units in the Dillon Transport Inc fleet. It is a shift that began paying dividends from the very start.

Specializing in the transportation of liquid and dry bulk cargoes, Dillon Transport started its move to natural gas-fueled vehicles in 2011, and it will be one of the first fleets to take delivery of tractors with the new Cummins Westport ISX12 G engine that launches in early 2013. Today, 25 of the carrier's 370 tractors run on natural gas, but management expects to more than double the number of natural gas-fueled trucks over the next six months.

“This project was in the works for about four years, and it has been a great move for us in so many ways,” says Jeff Dillon, president of Dillon Transport, which is based in Burr Ridge, Illinois. “We believe the move to natural gas power will be a game changer. It is already opening doors to more customers. Many of these companies want to work with fleets that have a green focus in their own operations.

“Natural gas is cleaner, cheaper, and domestically abundant. These factors benefit every US citizen in the form of environmental stewardship, national security, and job creation. We are proud to be a leader in the use of LNG (liquefied natural gas) as a transportation fuel. Our goal is to continue to field natural gas vehicles in support of our strategic partners' initiatives of environmental stewardship and cost reduction.

“The sustainability aspects of this fuel simply can't be ignored. Throughout the supply chain, there is more demand for use of greener fuels to haul their products. We believe shippers will pull more carriers into natural gas in coming years.”

Construction materials

Many of the companies served by Dillon Transport produce and ship materials used by the construction sector. The truck fleet started in 1980 as a construction hauler with a single tractor and dump trailer. By 1985, Dillon Transport had bought its first tank trailers and was expanding into asphalt hauling.

Today, construction materials account for about 80% of the cargoes hauled by the carrier. Asphalt is the dominant construction product hauled and will remain very important, but the carrier has diversified into other liquid bulk cargoes, including resin, phosphoric acid, lubricants, and crude oil. The carrier also hauls industrial materials and other dry bulk products.

With the focus on the construction sector, it isn't really surprising that the tank truck carrier began its push into natural gas fueled tractors in Dallas, Texas, hauling limestone filler and sand for Owens Corning, a leading global producer of residential and commercial building materials, glass-fiber reinforcements, and engineered materials for composite systems.

Growing NG fleet

Dillon Transport started with 14 natural gas-fueled trucks in Dallas and quickly added 10 more to serve another Owens Corning plant in Seville, Ohio. Tractors run 1,000 miles a day on average in the Dallas operation, and those in the Seville area run approximately 950 miles a day.

“We're hauling 80,000-pound loads in these operations,” says Charles Musgrove, vice-president of Dillon Transport. “These are slip-seat operations, and each driver makes two trips per shift. For maximum efficiency, we are employing a drop-and-hook system, and we have our own personnel at the plants to load and stage trailers. Most of the hauls are on interstate highways in what are essentially flatland conditions.”

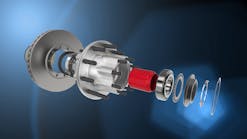

The engine chosen initially for this operation was the 8.9-liter Cummins Westport ISL G with spark ignition and a three-way catalyst for emission treatment. This engine definitely has proven that it can perform well in the right tank truck application, according to Musgrove. In addition to dry bulk loads, trucks with the ISL G have been used to haul some asphalt shipments. A liquefied natural gas (LNG) fuel tank with an 81-gallon diesel equivalent gives the tractors a range in excess of 400 miles.

“We chose the ISL G and LNG fuel for several reasons,” Musgrove says. “It helped us keep tractor tare weight in the 14,000-pounds range. With spark ignited ISL G, we didn't need the heavy selective catalytic reduction emission treatment systems now required on diesel-fueled trucks. In addition, LNG can be carried more compactly in smaller fuel tanks.

“There was a learning curve with the new equipment, and one challenge for our drivers was becoming comfortable with the range our tractors have with LNG. They wanted assurance that they had enough fuel to complete each trip. After almost a year with the engines, our drivers have completely accepted the engines.”

Dillon adds that the 8.9-liter ISL G has done well in the Owens Corning application. “Ninety-percent of those hauls are on interstate highway, and we really need no more than 180 horsepower for that,” he says. “We went with the 8.9 liter engine initially because we felt we couldn't wait for the release of the larger (Cummins Westport) ISX12 G. We had shipper contracts coming open, and we had to move quickly.”

Dillon Transport managers quickly saw what the ISX12 G had to offer, because the carrier was one of the test fleets. The carrier put a test truck with the ISX12 G on the road in August 2010, and it has performed very well. Cummins installed the test engine in a Dillon Transport Model 388 Peterbilt with a sleeper. The truck was outfitted with dual 150-gallon LNG tanks allowing runs in excess of 700 miles before having to refuel.

Available in early 2013, the ISX12 G comes with a range of power ratings up to 350 horsepower and 1,450 lb-ft of torque. Later models will be raised to 400 horsepower. A variety of engine brake and manual and automatic transmission options are available.

The carrier will be adding tractors with the new engine as soon as it is available in 2013. “We'll be expanding our natural gas fleet, but we also probably will replace the first group of tractors somewhat ahead of schedule,” Dillon says. “Our regular replacement schedule for the natural gas trucks would be four years, which means roughly 700,000 to 800,000 miles per tractor.”

More fuel

Increased power is just one of the reasons for quicker replacement. Tractors with the new 12-liter engine also will have more fuel capacity. “More fuel capacity means our tractors will have a range of 600 to 700 miles, compared with 400 miles for the tractors with the ISL G engines,” Dillon says.

In Dallas, LNG tractors refuel at the new Clean Energy station that was built on Dillon Transport's terminal property. LNG is shipped to the filling station from Clean Energy's liquefaction plant in Willis, Texas — on the north side of Houston.

Currently, this is the only public access LNG/CNG filling station in the Dallas area. Open since September, the station was under construction since March.

In Ohio, Clean Energy added an LNG fueling station at the Pilot Flying J Truck Travel Centers location in Seville to serve the Dillon Transport operation. Both Clean Energy natural gas filling stations are open 24/7 for public access.

A long-time buyer of Peterbilt tractors, Dillon Transport selected the Model 384 daycab for the natural gas power application. Diesel fueled Model 384 daycabs also are being used in Dillon Transport's relatively new crude oil hauling operations in South Texas. Peterbilt Model 388s are being used to transport process water in the oilfield operation.

In addition to the Cummins Westport natural gas engines, the Owens Corning-application trucks are spec'd with Allison 4500RDS automatic transmissions and Dana Spicer tandem-drive axles. “The Allison automatic transmission has been fantastic,” says Jeffrey Bonnema, Dillon Transport director or maintenance. “We have had no maintenance issues. It is rugged, and it takes abuse the trucks are put through.”

Dillon Transport also is specifying Bendix roll stability and air disc brakes for enhanced safety. Safety equipment in the newest tractors includes the Iteris lane departure warning system. Tractors also have Qualcomm on-board computers with electronic driver logs.

Trailer fleet

The newest dry bulk trailers being use to serve the Owens Corning account were built by MAC Trailer Inc and have a 1,050 cu ft capacity. “These dry bulkers have great features, and we are using them to haul some frack sand in the oilfield, as well as serve our construction materials shippers,” Bonnema says. “The MAC trailers have a lower tare weight. Drivers say they feel more stable on the highway and have less sway. We like the appearance and pricing.”

New dry bulkers are specified with RMC Inc remote-operated domelids to keep drivers off the tops of trailers. “It significantly reduces the chance of a fall,” Bonnema says. “It also speeds the loading and unloading processes. The remote-operated domelids cut loading time by 10 to 15 minutes.”

“We chose the RMC product because it has relatively few moving parts and is easy to maintain,” he adds. “The lids do need routine realignment, and it is important to keep the manway rim clear of dust.”

Dillon Transport is putting Air-Weight on-board scales on tractors and trailers to maximize loads. Dry bulker hardware includes Bayco check valves and BTI Sandhog tees. “The Sandhog is a good tee with great product flow characteristics,” Bonnema says.

Running gear includes the ability to lift the lead axle on the trailer tandem when running empty. Raising the axle means less tire wear and better fuel economy. Trailers also have Hendrickson Intraax air suspension systems, Meritor WABCO roll stability, Meritor Tire Inflation System by PSI, and Michelin X-One single tires.

The newest crude oil trailers in the fleet were built by E D Etnyre Inc. The DOT407 tankers have an 8,400-gallon capacity. Hardware includes Betts butterfly discharge and internal valves, Titan Logix level gauges, and Scully overfill protection. ♦