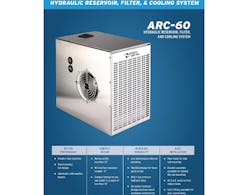

APSCO, a manufacturer of pneumatic and hydraulic valves and controls for the mobile equipment and transportation industry, recently introduce a new 60 GPM Hydraulic Reservoir, Filter and Cooling System—the ARC-60.

Manufactured at APSCO’s Tulsa OK plant, the ARC-60 is the second addition to the company’s ARC family of products that are designed to cool and condition hydraulic oil on mobile equipment and transportation applications with hydraulic drives.

“In developing the ARC-60, we listened to the voice of the customers and incorporated the popular features of our ARC-30 to ensure that our design and our features were market-driven,” said Chris Wunsch, vice president of sales and marketing for APSCO.

With a frame-mount design, measuring less than 13 inches wide and rejecting 28 horsepower of heat at 60 gallons per minute and 80° ETD (Entering Temperature Differential), the ARC-60 provides greater operating efficiency and longevity to the equipment’s hydraulic drive, APSCO claimed, while having the ability to be installed in tight spaces on either side of the vehicle. The ARC-60 is constructed from stainless steel and aluminum components, resulting in a corrosive-resistant unit suitable for the harshest environments.

Designed for ease of service, the components can be accessed and serviced by removing one panel, the company said.

“As with our ARC-30, our engineering team’s thoughtful design includes an integrated manifold system that reduces the ARC-60’s tube and hose components to just one low-pressure hose,” said Vince Williams, APSCO’s CEO. “This provides the owner or operator greater durability, lower maintenance and easier serviceability over alternative products.

“We are excited to introduce the ARC-60 to the industry. Manufacturing the ARC-60 at our plant in Tulsa allows us to produce and provide a quality product, and back it with APSCO’s high level of customer service and short lead times that we are known for.”

Email [email protected] or visit apscopower.com for more information.