As a matter of flat: The importance of high-quality flat seals in chemical transportation

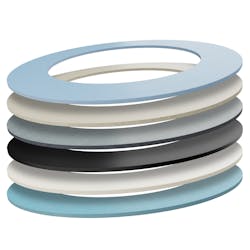

In the tank car industry, flat gaskets are the primary seal between the valve and tank car interface. They prevent leakage of liquids or gases, act as a barrier to contamination, and are critical for the safe and efficient transportation of hazardous materials. Each tank car requires multiple flat gaskets in a variety of sizes for varying hardware conditions.

A mighty flat solution

Flat gaskets are not a new technology, but their function is vital in preventing non-accidental releases (NARs) in the tank car industry where derailments and other issues frequently cause NARs which can harm the environment. Derailments like the one in 2023 in New Palestine, Ohio, have spurred governing bodies like the US Department of Transportation to increase safety measures for tank cars carrying flammable or explosive products.

Fire-resistant and fire-retardant flat gaskets made from flexible graphite material can help prevent flammable liquids or commodities from leaking and igniting. Suppliers like Trelleborg have performed extensive testing that proves flexible graphite flat seals (HMF30 series) perform well with high temperatures for short durations as well as during ambient conditions.

Another topic of conversation affecting the tank car industry is legislation around per- and polyfluoroalkyl substances (PFAS) and the European Union’s potential restrictions of fluoroelastomers, perfluoroelastomers, and polytetrafluoroethylene (PTFE) materials. Most Trelleborg fiber gaskets are PFAS-free and Trelleborg’s HMF 17 and 18 Series FlatSeal gaskets show positive leakage performance against all gasket materials including their PTFE counterparts providing shippers and tank car owners in the EU and the US with comparable PFAS-free flats gasket options.

Easing supply chain woes

For tank car repair shop customers, valve equipment manufacturers, and fleet management companies, it is important to have an alternative source when there are supply chain issues. The past few years have seen numerous supply chain interruptions due to Covid, weather, and geopolitics. Although supply chains are normalizing, approving alternative materials, like Trelleborg’s HMF FlatSeal gaskets, gives customers another source of supply and added peace of mind. Additionally, parts suppliers that have flat gaskets in stock help reduce downtime due to maintenance, ultimately contributing to the bottom line for shippers and fleet management companies.

Creating a quality product

When producing flat gaskets for flange applications in the chemical transportation industry, an expert parts supplier will oversee every step of the process from compound formulation to cutting the gasket, and everything in between. They will combine superior raw materials with quality control measures in the mixing and calendaring processes for outstanding and consistent product performance.

Chemical transportation customers should talk to their components supplier to ensure they are using approved materials that meet exact production specifications. A true expert supplier understands that the entire manufacturing process for flat gaskets is sensitive to fluctuating temperatures and invests in automated systems to monitor and control each step of the process from mixing the ingredients to the pressure and speed of the calendaring rollers.

Finally, parts suppliers should have measures in place for manual quality checks to ensure the sheet matches the intended thickness and that they have the capability to add coatings and printing to the gaskets.

Passing the test

- Leak testing: Measures flat gasket sealing performance by compressing gaskets at varying surface pressures with a leak rate measured over time.

- Loading and unloading curves: Shows leakage performance by increasing surface pressure on the gasket (loading curve) and how the material performs as the system relaxes (unloading curve). Since decreasing surface pressure is almost unavoidable in pressurized sealing systems, a professional leakage test requires loading and unloading curves.

- Residual stress testing: Investigates the mechanical behavior of the gasket material due to relaxation over time at elevated temperatures. This test provides insight into the gasket material, indicating its ability to withstand higher application temperatures.

- Fluid testing: Measures the material response to different types of media by immersing gaskets in fluids for a set period. Measurements determine changes in weight and thickness and indicate the chemical resistance of the sealing material.

Conclusion

When shippers, repair shops, valve equipment manufacturers, and fleet management companies have access to flat gaskets that offer superior performance it helps minimize total cost of ownership by reducing downtime and maintenance and ensures a high level of safety. A reliable expert component supplier will perform extensive testing on their flat gasket materials and the most comprehensive suppliers will do competitive testing to demonstrate how their materials compare to others in the industry.

Brett Hopkins is the technical manager for chemical transportation at Trelleborg Sealing Solutions.