LAS VEGAS—From the expansive exhibit hall at CONEXPO-CON/AGG 2023, Navistar launched the International S13 Integrated Powertrain for the vocational market Tuesday.

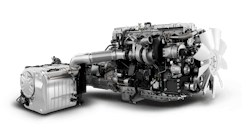

Developed from a “clean sheet” design, the S13 Integrated Powertrain consists of three distinct components—an engine, a transmission, and an aftertreatment system. But unlike existing powertrains on the market, which have evolved through a series of modifications to existing platforms as emission regulations became more strict, the S13 was designed and developed concurrently to ensure maximized compatibility and integration between systems.

See also: Navistar's new powertrain advances emission control

"The S13 Integrated Powertrain is the most advanced powertrain we've ever produced and the lightest vocational powertrain available on the market," Mark Stasell, Navistar VP of vocational truck business, said from the stage, surrounded by a range of International vocational trucks. “I'm thrilled to share how our new, optimized S13 Integrated will benefit vocational customers by achieving stellar performance, simplicity and serviceability, and superior operating economy."

Navistar first introduced the S13 Integrated Powertrain for the on-highway market in August 2022, available in the International LT and RH Series models.

Engine, aftertreatment innovations

Based on a modular design in global collaboration with the TRATON Group, the 13-liter International S13 engine achieves advanced fuel efficiency and performance through a clean-burn combustion strategy and a reduction of friction and pumping losses, according to the manufacturer.

With selective catalytic reduction (SCR) technology as the primary emissions reduction technology, the resulting absence of an exhaust gas recirculation (EGR) cooler on this engine allows for nearly 100 percent of exhaust to flow to the fixed geometry turbocharger—equating to more power and improved engine performance. Additionally, the engine operates on low revolutions and high torque, which equates to fewer fuel injections and less fuel consumption, delivering up to 515 horsepower and 1,850 lb-ft of torque, Navistar reported.

The design of the Dual Stage Aftertreatment is built with easy access for serviceability, as well as significantly improved emissions control and fuel efficiency. Since an EGR cooler was eliminated from the combustion process, less soot and particulate matter are generated. This cleaner combustion cycle allows for extended service intervals and eliminates the need for the diesel oxidation catalyst (DOC) and active regeneration.

"Vocational trucks often spend quite a bit of time idling on a job site which has historically required more frequent active regens," said Stasell. "The aftertreatment system of the S13 Integrated Powertrain, combined with the engine combustion strategy, vastly reduces the need for both active and parked regens."

Transmission, PTO Options

Of note for job site applications where extensive backing is necessary, the International T14 Transmission, a 14-speed automated manual transmission (AMT), uniquely combines the transmission’s low range and six reverse gears through the use of a planetary gear set.

The T14 combines two deep crawler gears and a wide 26.7 overall ratio to provide slow-speed maneuverability, exceptional startability, and enhanced performance running to and from the job site.

The T14 Transmission features vocational-specific drive modes, including off-road mode, manual mode, and paver mode. These drive modes combined with other vocationally focused functionalities, such as split-shaft mode and rocking mode, which breaks the truck free when stuck.

Multiple spec'ing options are available for various vocational customer applications, including front-engine power take-off (FEPTO), rear-engine power take-off (REPTO), as well as single and dual output transmission PTOs.

All PTO options are factory-installed at Navistar's Integrated Powertrain Plant in Huntsville, Alabama, and carry the warranty of the T14 transmission.

The S13 Integrated Powertrain also takes advantage of Navistar's Diamond Logic electrical system to optimize body integration, convenience, and safety features. This provides both chassis upfitters and customers maximum flexibility, simplicity, and functionality.

This story originally appeared on ConstructionEquipment.com.