FMCSA, Transport Canada officials spotlight new rules, standards affecting transportation of hazardous materials

REPRESENTATIVES from the Federal Motor Carrier Safety Administration (FMCSA) and Transport Canada (TC) highlighted updates on rules and regulations affecting tank truck carriers and tank manufacturers in North America during Tank Truck Week 2018 in November in Nashville, Tennessee.

Paul Bomgardner, FMCSA’s hazardous materials division chief, focused on special permits, key exceptions, tank vehicle definitions, and the most common violations roadside, by tank facilities and manufacturers.

Chris Nowak, a containment and regulatory affairs expert for Transport Canada, touched on recent and upcoming regulatory and standards changes affecting carriers, tank manufacturers and cargo tank manufacturers.

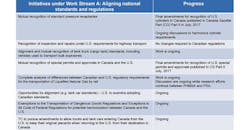

His presentation covered a number of pertinent issues, including training for carriers, and tank inspectors and testers, Emergency Response Assistance Plan (ERAP) requirements and the continuing work of the Regulatory Cooperation Council (RCC) to align standards in Canada and the United States.

FMCSA reviews special permits for highway transport when the requests are for emergency processing, technical review (primarily involving cargo tanks), or new, renewed or “party-to” special permits (SP) from interstate and intrastate carriers holding a hazardous materials safety permit (HMSP).

However, these requests officially reach FMCSA rather circuitously.

Bomgardner said he forwards SP requests, even the ones for emergency processing, to the Pipeline and Hazardous Materials Safety Administration (PHMSA), which reviews them—then returns them.

“It’s kind of a backward way to do things, because the only thing I do … as soon as I get it, is send it over to PHMSA, so they can put it in their system, and then they send it back to me to ask whether or not it needs emergency processing,” Bomgardner said. “So it’s kind of a strange setup we have, but it’s in the regulations.”

To expedite processing, he recommends sending SP requests to both organizations simultaneously.

PHMSA reviews incident data and other relevant information, including the carriers’ credentials, then sends the request back to FMCSA, which looks at Compliance, Safety and Accountability (CSA) scores and insurance levels, among other factors, before approving or denying a request.

An FMCSA review can be a quick “desk top” audit, or far more thorough vetting.

“If they don’t meet the parameters, that special permit comes over to us for further investigation,” Bomgardner said. “We’ll take a look at the carrier’s safety profile. We’ll go back a year, take a look at the last 12 months of activity, and if there’s not enough information there for us to make a determination during a desk audit, we’ll send it out to the field for on-site investigation.”

During a seven-year snapshot of SPs reviewed for PHMSA from 2011 to 2018, FMCSA received 1,483 applications, closed out 1,469, approved 928, denied 376 and returned 165 to PHMSA.

Hazmat safety permits

FMCSA also issues Hazardous Materials Safety Permits (HMSPs) for carriers transporting more than 55 pounds of explosives, various levels of materials that are toxic by inhalation, and compressed or refrigerated liquified methane and natural gas, or other liquified gas with a methane content of at least 85%.

The biggest recent change to HMSPs involves transporting hydrous ammonia.

In October 2017, FMCSA attorneys decided domestic anhydrous ammonia does not meet the definition of a material that requires an HMSP based on the way federal regulations currently are worded.

International anhydrous ammonia, however, does require an HMSP.

“It’s odd if you think about it, because domestic anhydrous is the same product as international anhydrous, except for the fact that under domestic, we transport it as a (Division) 2.2 (Inhalation Hazard),” Bomgardner said. “You can’t assign PIH (Poison Inhalation Hazard) zones to a 2.2. There’s no such thing.

“So our attorneys said, ‘OK guys, since we can’t assign a zone, it can’t meet the definition of a Zone D material.’”

Bomgardner warned against checking every box when requesting an HMSP.

He said some carriers do this thinking they might transport this chemical or that product sometime in the future, but carriers checking boxes unnecessarily are at risk of having permits cancelled.

“If you don’t need a hazmat safety permit, don’t say you need one, because if you do that and we come out and take a look at your company, and determine that you have not carried this stuff and have no contracts to carry it, we’re going to take the hazmat safety permit away from you,” Bomgardner said.

And if an HMSP isn’t needed, carriers are better off without it.

“If you want more scrutiny than you have now, be a hazmat safety-permitted carrier, because we take a look at you all the time,” Bomgardner said. “You are constantly being reviewed in our system.”

Cargo tanks

Many carriers would like to see the tank vehicle definition laid out in Section 383.5 change—or go away completely.

They’re not, Bomgardner said.

This means drivers transporting four 250-gallon totes need a Commercial Driver’s License, because the aggregate is 1,000 gallons, and carriers moving Compressed Natural Gas (CNG)—which Bomgardner called the “latest and greatest thing to transport”—in cylinders manifolded together still need an HMSP if their total is more than 3,500 gallons because of the high methane content.

For more cargo tank resources, visit fmcsa.dot.gov/carrier-safety/hazardous-materials-safety/cargo-tank-registration-and-resources.

The top five cargo tank manufacturer violations FMCSA sees involve insufficient training, recordkeeping and accident damage protection, and unqualified design certifying engineers and registered inspectors (RIs).

Training issues include a general unawareness or unfamiliarity with regulations, particularly those involving specific functions, safety or security, and a dearth of required hazmat employee training.

“(Some tank manufacturers) don’t believe that they’re hazmat employers,” Bomgardner said. “Well, you are.

“If you’re manufacturing a specification tank, you’re a hazmat employer.”

The most common cargo tank facility violations include failures in retraining hazmat employees every three years, and performing leakage tests and external visual inspections as prescribed.

FMCSA issued a key interpretation regarding undocumented repairs to cargo tanks in October 2018.

“If you have welded repairs to your cargo tank (made after 2003) … and can’t show the facility doing the visual inspection, where you had that repair done by a R- or U-stamped shop, you’re going to have to get it re-repaired,” Bomgardner said. “You can’t have an RI look at that and say everything is OK.”

Common roadside violations include packages not properly secured and problems with shipping papers.

“It’s amazing that this really never changes,” Bomgardner said.

Bomgardner also mentioned the ongoing work of the Cargo Tank Advisory Group, which includes the National Tank Truck Carriers (NTTC), Truck Trailer Manufacturers Association (TTMA), Burch Tank, National Tank Services, Trimac and Wabash National, on the two-year Triple Issues Study.

The biggest development, he said, is the conception of TankFax, which, like CarFax, will track a cargo tank from “birth to death” with a comprehensive database that eliminates many issues with facilities misplacing vital records. FMCSA hopes to develop and conduct a pilot program in the future.

Transport Canada

Nowak’s updates centered on Parts 6 and 7 of Transport Canada’s Transportation of Dangerous Goods (TDG) regulations, and Canadian Standards Association (CSA) Standards B620, B621 and B622.

TDG Part 6, which covers training, is receiving an update in an effort to “increase compliance and improve public safety” by ensuring people who transport dangerous goods have the knowledge and skills to perform their jobs, and increasing the clarity of the regulatory requirements.

After recent policy consultations, Transport Canada plans to incorporate a competency-based training and assessment standard with a general awareness training component into the amended regulations.

Technical committee working group meetings are ongoing, Nowak said.

The Part 7 update is intended to enhance the capacity to respond to transport emergencies through improvements to ERAP requirements, including who can activate an ERAP and ERAP response.

Transport Canada also plans to streamline and clarify requirements as needed.

Proposed amendments include a mandatory call to an ERAP number when a means of transport cannot continue to its intended destination without intervention, and a requirement for a technical advisor to respond to calls to the ERAP number at any time while the goods are in transport.

Criteria for ERAP activation includes compromised containment that endangers or could endanger public safety, an anticipated or required product transfer, and a release or anticipated release.

Final amendments are planned for publication in the Canadian government’s official newspaper, the Canada Gazette, in March 2019, which also is when the proposed changes would take effect.

TC standards

The most recent changes to Transport Canada’s CSA standards, which include requiring emergency discharge controls for new tanks—instead of bobtails only—under B620 took effect last year.

The 2014 edition also includes revised damage protection requirements for TC 331, TC 338 and TC 341 tanks.

“They seem to be a little more sensible,” Nowak said. “They were pretty heavy the way they were written in the standards.”

Other changes include mandatory post-weld heat treatment for new tanks transporting Anhydrous Ammonia, allowing mobile repairs of tanks, and optional insulation requirements for TC 423 tanks.

Critical changes to B621 and B622 mandate automatic engine air intake shut-off devices for diesel engines running during loading or unloading in Class 2.1 and Class 3 dangerous goods service, wheel chocks for loading and unloading highway trucks, and increased inspection and test frequency for existing non-specification ASME (American Society of Mechanical Engineers) nurse tanks.

Nowak also said TC is close to wrapping up the next edition of the standards, with enforcement beginning in mid-2020.

Pending changes include updating ASME code referencing to the most recent edition of the ASME code, revised tank securement requirements, and reintroduction of TC 51 portable tanks into B620 standards.

“This is going to alleviate a lot of headaches and problems over the years, and allow manufacturers to take advantage of the latest materials and processes,” Nowak said of the ASME update.

Visit tc.gc.ca/en/transport-canada.html for more information.