SAN DIEGO—As Navistar prepares for the market introduction of its “clean-sheet” International S13 integrated powertrain, the OEM is unveiling ownership solutions for dealer integrated software, built-in service products, repair maintenance contracts, and preventive maintenance programs.

Developed over five years through global collaboration with Navistar’s parent company, Traton Group, the S13 powertrain has been touted as the OEM’s cleanest and most fuel-efficient and diesel powertrain. All International on-highway models specified with the S13 integrated powertrain will come equipped for five years with solutions that include:

- OnCommand Connection (OCC) advanced remote diagnostics, with vehicle support through fault code prioritization

- Intelligent fleet care reports such as advanced fuel analytics and predictive fleet health monitoring

- Over-the-air updates for approved calibration and programmable parameters to engine and transmission software

- Gateway integrations that enable access to third-party fleet management and compliance providers without the need for additional telematics hardware

- A subscription to International 360, Navistar’s all-makes service communication tool designed to accelerate the repair process and streamline dealer communications

OCC utilizes data from the vehicle to continuously improve parts stocking at dealer locations. Focused on maximizing customer uptime, dealers will have the critical parts for the S13 Integrated Powertrain stocked at key locations nationwide when the powertrain enters full production. Navistar will then continue to ensure parts are stocked by leveraging machine learning algorithms.

“The good thing about data-based decision making for parts availability is optimizing the parts inventory in the dealer network so we know we have the right parts at the right time for dealer locations,” Göran Nyberg, EVP of commercial operations at Navistar, told FleetOwner during American Trucking Associations' 2022 Management Conference & Exhibition in San Diego. “That’s important for the new powertrain and to make sure our dealer network is prepared for the new powertrain.”

See also: Closer look: Navistar’s new powertrain advances emission control

Further, Navistar is setting up a combination of online training sessions, bootcamp training, and repair training for fleets and its dealer network.

“We have a training facility near our Lisle, Illinois, headquarters, and we’ve had events where people are coming in there and actually tearing engines apart,” noted Chet Ciesielski, Navistar’s VP of on-highway truck business. “It’s all part of getting people comfortable with this integrated powertrain.”

International LT Series or RH Series models specified with the S13 engine will include a two-year, unlimited mileage base engine warranty, and a five-year or 500,000 miles warranty for major engine components. Additionally, the T14 transmission will have clutch coverage for three years or 350,000 miles and power take-off coverage for five years or 750,000 miles.

A 'clean-sheet' design

Navistar introduced the International S13 integrated powertrain to dealers, customers, and industry press at an event in Las Vegas this past August. Set to enter production in July 2023, the powertrain continues to undergo extensive testing to ensure proper validation for the North American market, with more than 4 million road miles and over 50,000 dyno hours completed to date, according to Navistar.

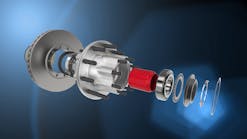

Diane Hames, Navistar’s chief marketing officer, emphasized that the new powertrain truly is a “clean-sheet” design, where the OEM leveraged the technologies in place today to eliminate a lot of problem areas and complexities, such as removing the need for an exhaust gas recirculation (EGR) cooler, variable-geometry turbocharger, and active regens.

“We have a completely different combustion philosophy and a completely different clean combustion cycle,” Hames told FleetOwner. “There is no cool EGR, which gets rid of a lot of soot and ash problems. With passive regeneration, from an uptime perspective you don’t have to take the truck out of service for active regens or other failures. It’s been designed to take some of the regular service intervals out, like the ash cleaning on the DPF, and extend those further based on the design philosophy of the engine.”

Navistar executives have maintained that the powertrain’s reimagined dual-stage aftertreatment system, devised concurrently with a selective catalytic reduction-based engine, solves many revenue-depleting and downtime problems via reduced complexity and increased serviceability.

This article originally appeared on FleetOwner.