Kenworth and Dana say they are collaborating on electric powertrain development for medium-duty Kenworth battery electric vehicles. An example of that collaboration, a Kenworth K270E battery electric truck, was on display at the 2020 Consumer Electronics Show in Las Vegas NV.

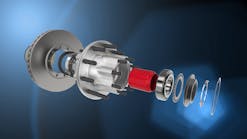

The zero-emissions Kenworth K270E cabover on exhibit at CES is equipped with Dana-designed e-Powertrain system that is fully integrated and upfitted to the Kenworth chassis. Configured as a direct drive system, the vehicle utilizes a Spicer® Electrified e-propulsion system, and a standard Dana drive axle and driveshaft.

Dana also supplies an e-power system, which generates, stores, and manages the energy for the vehicle and consists of electrified auxiliary systems, an on-board charger, and two battery packs. Dana-developed software and controls enable the diagnostics and telemetry of the complete system.

The electric powertrain will be available with range options between 100 and 200 miles. The state-of-the-art, high-energy density battery packs can be recharged in about an hour using the vehicle’s DC fast-charging system, making both the Class 6 Kenworth K270E and Class 7 K370E cabovers ideal for local pickup and delivery, as well as short regional haul operations.

“This is an important next step in our evolution of an electric powertrain,” said Kevin Baney, Kenworth general manager and PACCAR vice-president. “Dana is an industry leader in electrified modules and systems supported by in-house vehicle integration expertise. Kenworth plans to produce up to 100 medium-duty cabover electric trucks in 2020.”

Mark Wallace, president of Commercial Vehicle Drive Technologies for Dana, added: “As demand for clean, electric-powered vehicles continues to grow, we are pleased to collaborate with Kenworth by providing the design, integration, and upfit of the complete e-powertrain for the K270E electric truck. Kenworth’s commitment to providing advanced vehicle technologies, combined with our proficiency in delivering end-to-end turnkey electric systems, will result in high-efficiency solutions that greatly reduce the total cost of ownership for vehicle operators.”

Kenworth also exhibited a Level 4 Autonomous T680 in the PACCAR booth during CES. The proof-of-concept truck was conceived and constructed at the PACCAR Innovation Center.

PACCAR has worked with leading experts in the field of high-definition mapping, localization, perception and path planning to deliver an integrated autonomous solution. The special Kenworth T680 is equipped with cameras, LiDAR (light detection and ranging) sensors, and radars to sense the surrounding road environment and to feed fusion algorithms in the perception stack for object identification and tracking.

A Global Navigation Satellite System with an Inertial Measurement Unit combined with LiDAR Point Cloud on a high-definition map provides centimeter accuracy localization. The autonomous vehicle software and feedback control logic for actuation are hosted on five computers that record up to 1TB of data per hour of driving.

Mechanical modifications to the Kenworth T680 include redundant steering torque overlay system, upgraded high capacity alternator, a high-fidelity electronically controlled air braking system, and the addition of rear seats in the sleeper structure for the autonomous engineering team.

“Kenworth and the PACCAR Innovation Center in Silicon Valley are working closely together to explore and develop the latest advanced driver assistance systems and other new technologies that offer safety and efficiency benefits for truck fleets and drivers. The Level 4 Autonomous Kenworth T680 is a perfect platform to study this technology in real-world applications,” said Patrick Dean, Kenworth chief engineer.