CIMC recently delivered the first batch of newly built T50 gas tanks with vertically mounted V-shape baffles to Netherlands-based Trifleet Leasing.

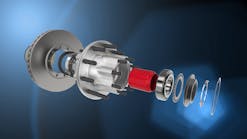

The safety-enhancing baffles make it easier for internal inspections and maintenance, the companies reported. And in the event of a safety incident, assistance to or recovery of the person involved is easier. Also, this design has an improved surface coverage of 60% to 65% compared to the 50% coverage of the old design.

“Trifleet and its employees strive toward sustainable excellence and always take that extra step to deliver the best,” Trifleet stated in a news release. “Together we are creating a safer and more sustainable global supply chain. As a GATX company, Trifleet is championing the well-being of our employees and communities.”

One of the critical safety concerns is the risk associated with entering tank containers for inspection, maintenance, or cleaning. Confined spaces within these containers pose hazards such as oxygen deficiency, exposure to harmful substances, and the risk of explosion. Regulatory bodies have responded by mandating stricter procedures for confined-space entry, leading to the new tank design.

Baffle plates are installed inside tanks to stabilize the product and prevent sloshing. Sloshing refers to the movement of the product inside the tank containers that can be caused by sudden driving conditions such as braking and cornering. When horizontal baffle plates are fitted, it is difficult to recover an unconscious person in case of an accident.

With vertical baffles, recovery time and effort will reduce drastically, Trifleet said.