Beall Corp expands tank repair capabilities during recession

ECONOMIC downturns are “Opportunity Times,” according to James Beall, president of Beall Corporation. The Portland, Oregon, company made very good use of the most recent downturn in its cargo tank repair and service operations.

Over the past year, Beall Corp expanded service capabilities in the Portland shop to include cryogenic tanks. The company opened a new 32,000-sq-ft facility in Salt Lake City, Utah, and expanded the shop in Sunnyside, Washington. An 8,000-sq-ft addition to the shop in Kent, Washington, was just completed in February 2010.

“Having been around for 105 years, Beall Corp has experienced many business cycles and has always taken advantage of down business cycles to grow,” Beall says. “Real estate, businesses, and high-quality employees become available in tough times. If you are able to seize those opportunities when they present themselves, you can put more distance between yourself and the competition.

“We are very optimistic about 2010. By upgrading and diversifying our service capabilities, we believe we can appeal to a broader customer base. A very small portion of the federal stimulus funding allocated to construction projects made it down to the contractor level in 2009. We expect more stimulus-related activity in 2010. In addition, carriers hurt by lower shipment volume in this downturn delayed maintenance and conserved cash. Pent up demand for repair work is just starting to surface.”

Major investment

Wayne F Kimmet, vice-president of operations for Beall's parts & service division, adds that the company invested more than $3 million in the repair shop expansions and upgrades that reinforce the drive to be the leader in trailers, parts, and service. In addition to expanding the size and scope of its tank repair shops, Beall added manpower.

“The improvements we made enable Beall to provide our customers with faster service turnaround times,” Kimmet says. “More facilities across the country make it more convenient for our national fleet customers to get to a Beall facility. Larger parts inventories lead to better availability.

“Our tank manufacturing culture extends to our repair facilities, and our mechanics are craftsmen experienced in fabrication and all phases of tank repair and testing. Our rigorous weld certification, ongoing safety, and compliance training overseen by two compliance engineers ensures that the job is done correctly. Our staff of 20 engineers lends support to all of the Beall facilities.

“We love the tough projects. Our standard on every job is that weld quality, fit, and finish will measure up to the high standards of a brand new Beall trailer rolling off the factory floor.”

More service bays

The recent facility expansions increase Beall's repair capability to 172 service bays with 171 mechanics and welders. All shops are National Board Inspection Code-certified “R stamp” facilities offering cargo tank testing, repair and modifications, fabrication work, and major wreck rebuilds for all trailer types. Beall facilities stock more than $20 million in heavy-duty truck and trailer parts, and the company is a member of the VIPAR Heavy Duty Network.

Beall's Parts and Service Centers are in Kent; Sunnyside; Portland; Billings, Montana; Dickinson, North Dakota; Denver, Colorado; Salt Lake City; Phoenix, Arizona; and Bloomington, Turlock, Fresno, Oakland (Trailco), and Sacramento (Pacific Tank Truck), California. Manufacturing plants in Portland and Salem, Oregon; Sunnyside; Billings; Turlock; and Phoenix build tank trailers, pneumatic dry bulkers, dump bodies, and bottom dump trailers.

Beall recently completed a retrofit project that converted an existing bay at the truck repair shop in Portland into a dedicated clean room for servicing cryogenic trailers used to transport high-purity and medical-grade gases. Assembling the clean bay included building a wall to separate the bay from the rest of the shop; enclosing plumbing, heating, and mechanical fixtures; installing an air-tight access door; and sealing the floor with industrial-grade epoxy.

The result is an air-tight bay that provides a sterile work environment free of dust and contaminants. Maintenance services available for cryogenic tanks include tank testing, vacuum leak detection, and weld repairs to the inner vessel, jacketing, and annular space.

Specially trained and qualified mechanics working in the clean bay must wear protective coveralls while working on the cryogenic tanks. Cryogenic tank service equipment includes state-of-the-art helium mass spectrometer for detecting vacuum leaks, an ultra-low vacuum pump, and a variety of specialized tools.

“Adding the clean bay was a logical step for us,” Kimmet says. “We've been testing these specialized cryogenic tanks for many years, but we had limited repairs and modifications to subframes, plumbing, and the outer jacket. We had seen a demonstrated demand in the western United States for vacuum leak testing and inner vessel repairs, and we responded to that opportunity. Currently, there are more than 1,000 cryogenic tanks on the West Coast, and some of the operators are traveling more than 1,000 miles to get repairs.”

Salt Lake City

The new parts and service center in Salt Lake City replaces another facility that Beall had outgrown. “With so much tank repair work in the area, we had outgrown the four-bay, 6,500-sq-ft shop we moved into in 2006,” Kimmet says.

Beall's new 32,000-sq-ft Salt Lake City parts and service center was completed in April 2009 and sits on five acres. The building houses administrative offices, a large parts warehouse, and 20 service bays. It was outfitted with new fabrication equipment, including a 12-ft/175-ton press brake, 10-ft shear, ironworker, horizontal and vertical band saws, layout tables, drill presses, grinders, and MIG and TIG welders. A storage tank holds 13,000 gallons of water for hydrostatic cargo tank testing.

“Like the rest of our “R-stamp” shops, the Salt Lake City location is capable of fabricating all of the parts needed for a full rebarrel, with the exception of heads, baffles, and rolled shells — all of which are supplied from our factories in Portland and Billings,” Kimmet says. “Our facility staff stands at three administration employees, six parts department employees, two service managers, and 16 high skilled mechanics. The team includes nine experienced tank mechanics that joined us when we acquired a major customer's tank maintenance operation in June 2009. We've also added two top construction equipment mechanics for dump bed work.”

Three bays were added to Beall's Sunnyside facility in June 2009, and are primarily dedicated to cargo tank testing and repair. The shop also handles some repair work on pneumatic dry bulk trailers and construction equipment for customers in central and eastern Washington.

Kent expansion

Beall will complete an 8,000-sq-ft expansion at its Kent parts and service center in February. The expansion includes a new parts showroom, warehouse, and an additional bay for tank mounting. Prior to the expansion, the Kent facility covered 12,000 square feet and had 10 service bays. Steam rack equipment was upgraded. Along with the facility expansion, Beall hired additional parts sales employees and two mechanics as part of a push to gain a bigger share of the market in the Seattle, Washington, metro area.

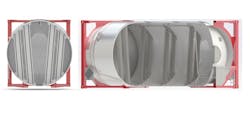

Additional expansion initiatives are likely through the rest of 2010. Beall plans to add tank lining installation and service. The company also is laying plans to expand into ISO container inspection and repair. On a larger scale, the company has targeted three major markets as good candidates for parts and service centers.

Finally, parts sales activities are likely to grow. “Because of our size, our large parts inventory, and wide geographic footprint, we believe we are well positioned to meets the growing customer demand that will come with a recovering economy,” Kimmet says. “During the recent Heavy Duty Aftermarket meeting in Las Vegas (Nevada), we got the sense that the worst of the downturn is over, and a slow recovery is beginning. We can react quickly to help carriers get idle equipment back on the road as the economy gains

momentum.” ♦