Dynamic development: Pilot tests advance smart tanker utility

Scour the exhibit hall floor at any truck show, and you’ll spot every solution needed to operate an extremely efficient fleet. The rub, says Brent Hickman, senior manager for equipment, maintenance, and fleet sales at Pilot Company—which boasts a fleet of nearly 1,800 tank trailers—is you'd need 12 subscriptions and nine people to manage them.

The search for one solution to unite them all led Hickman to Drōv Technologies’ all-inclusive AirBoxOne—an advanced electronics and pneumatics control platform with incredbile connectivity, expandability, and functionality.

“What sets this system apart is, it’s not trying to replace OEM parts,” he explained to Bulk Transporter. “It’s directing traffic using the equipment that’s there, just with one source. And with the rush to deliver technology to the trucking industry—into trailers, and even tractors, for that matter—there are a ton of people flooding the market with solutions. But one solution here and another one there, for every different need, doesn’t make sense to a lot of fleets. So an all-in-one package that eliminates the silos is a huge win.”

But system integration was only the first of several successes for Pilot, which connected with Drōv two years ago at the Technology & Maintenance Council’s annual meeting. Their collaboration soon evolved into testing tank trailers outfitted with myriad smart features, including electronic tire-pressure controls, and weight and temperature sensors that enable more efficient loading—and highly compelling “dynamic tire inflation.”

See also: Drōv’s AirBoxOne makes tank trailers smarter

Their work indicates automatically inflating and deflating tires based on weight and location extends tread life—saving fleets an average of more than $1,000 per trailer, per year. “Doing this, I knew we were going to see nice savings,” said Bob Davis, Drōv vice president of business development, who is managing the project.

“I didn’t know it’d be over 50% [better tire life], but Brent has the numbers to prove it.”

Engineered Transportation International (EnTrans) is a believer. The Heil and Polar tank trailer parent recently signed an exclusive two-year deal that makes AirBoxOne the centerpiece of its newly rebranded TankAI intelligent trailer system, which Jake Radish, SVP of sales and marketing at EnTrans, says can generate a $25,000 return per unit each year. And carriers like Pilot, Mohsen, and Tidewater Transit are buying in, helping EnTrans log 100 orders for TankAI-equipped petroleum trailers in the first four months of 2023.

“People don’t want all these different user interfaces, and data plans they have to manage, so we’re bringing it all together under one roof—where you’re offered a fully comprehensive technical solution,” Radish said.

Productive partnership

EnTrans and Drōv began collaborating last April after meeting at National Tank Truck Carriers’ 2022 Annual Conference in San Diego, California. Radish said he appreciates Drōv’s enthusiasm for creating customized smart-trailer programs for its vendor and fleet partners. “They’ve been able to work with us, Pilot, and our various other customers, to develop solutions that work for them,” he said. “Instead of being that company that claims they know it all, they are raising their hands and asking, ‘Hey, what works for you?’”

Hickman concurred, saying new upside emerged through cooperative development. “That’s one of the great things about working with Bob and [Drōv CEO] Lisa [Mullen] and that group,” he said. “If you walk around and talk to a lot of suppliers at shows, you often get the sales pitch, and that’s fine. But if you say, ‘I have a fleet, and I like your product, but it’d be more beneficial to me if it did this,’ typically you see some resistance. It’s, ‘Oh, this will work if you change your fleet procedures.’ Well, that’s not viable for a lot of folks.

“And so their willingness to say, ‘OK, what do you need in this solution?’ has been very attractive, and very helpful.”

Pilot started testing two Heils retrofitted with Drōv’s AirBoxOne and Drōv SI (standard inflation) system in June 2022. Now EnTrans is integrating AirBoxOne units with Hendrickson suspensions and TireMaax tire pressure control systems on new builds in Athens, Tennessee. Pilot has 18 trailers in service with TankAI systems—which EnTrans introduced commercially in Q4 2022—and more on order, Hickman said. “It combines what’s proven in the market, and readily available from Hendrickson as the TireMaax system—including plumbing, axles, seals, and wheel-end components—with all the features available in Drōv’s AirBoxOne,” Radish said.

The suspension kits come fully dressed from Hendrickson, streamlining assembly for EnTrans, and preserving factory warranties and support for Pilot, which now can secure fully integrated smart trailers at one price. And the partnership is paying off for Drōv, which is rapidly increasing adoption by leveraging the strong positions of EnTrans and Hendrickson in the tank trailer market. “It’s exciting times,” Davis said.

“Everybody is starting to realize the power of the AirBoxOne.”

Dynamic tire inflation

The AirBoxOne is the first device to electronically control tire inflation and deflation, which typically is managed manually, Davis said. “Nobody’s been able to do that,” he maintained. “We can—and we take it a step further.” The result is dynamic tire inflation, which combines geofences, or GPS-defined virtual boundaries, with sensors to automatically finetune pressures based on real-time factors like temperature and gross combined vehicle weight—calculated to within 150 lbs. in combination with an “AirBoxLite” device in the power unit.

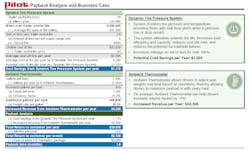

Hickman said he was replacing tires early because of “odd” tread wear. Using the AirBoxOne and Michelin X One Multi Energy T wide-base trailer tires, Pilot went from achieving 14,893 miles per 32nd of wear, with a traditional inflation system, to 32,649 miles per 32nd—a 54.4% increase, according to test results produced last year. That translates to six fewer sets of tires over a 20-year trailer life, for a total savings of roughly $20,000.

Dynamic tire inflation also protects against costly and dangerous roadside breakdowns—keeping punctured tires filled until the vehicle makes it home—and blowouts, Hickman said. And while overinflation isn’t the primary cause of “rubber on the road,” it can burst tires if left unchecked; and it’s not unusual to catch tire pressures at 140 psi in extreme heat, so fleets are “taking more of a risk by only inflating,” he argued.

Maximized returns

With automated pressure adjustments and remote access, driver involvement isn’t necessary, and weight sensors don’t need “wrench” calibrations. Pilot currently validates vehicle weights every three months, and Hickman believes they can extend it to six. “In a world of advanced technology, I’m looking at everything and asking, ‘How do we get more consistent … [and] eliminate as much human error as possible?” Hickman said.

Weight and ambient temperature sensors also unlock “max loading” based on vehicle weight, and the weight of the product entering the trailer—a gallon of diesel can weigh 6.7 pounds in Phoenix and 7.3 in New York, where it’s cooler, for example—without back-office support or time-consuming trips from rack to scale. Now drivers can more easily earn KPI-based incentives for max gallons without fear of overloading.

Hickman said Pilot is averaging 133 more gallons per load in tests in Oklahoma City, where it makes 1,250 deliveries each year, conservatively equating to eight fewer trips per year to transport the same volume of fuel. “We’ve seen anywhere from a 65-gallon-per-load increase all the way up to a 300-gallon increase,” he said.

EnTrans offers Drōv-powered TankAI petroleum trailers with four “lane” packages. Lane 2 includes dynamic tire inflation, wheel-end monitoring, and LoadGuard theft alert, which Circle K uses to detect offloading outside geofenced locations, Radish said. Lane 3 adds ambient temperature sensors and brake pressure monitoring, and Lane 4 (coming soon) features per-compartment ultrasonic fluid sensors and lading temperatures. And with dynamic tire inflation and ambient thermometers helping fleets maximize payloads, petroleum haulers can recoup the cost of the Lane 3 telematics package ($3,900) in less than two months—and realize a $25,000 annual return on investment, according to an EnTrans analysis of Pilot’s testing.

“It really is paying for itself,” Radish said.

Advanced adaptation

Efficiency-fueled savings and integrated solutions are helping accelerate smart trailer technology adoption—and more is on the way. Pilot and Drōv currently are testing systems that prevent load mixing and cross drops, and Drōv aims to one day control tractor and trailer tire pressures, instead of only monitoring tractor tires.

Hickman is sold on the AirBoxOne’s present-day and future-proofed utility.

While Pilot technically still is in a test phase, he’s considering equipping all new builds with Drōv-powered systems and developing a plan to retrofit newer existing trailers over time. “Retrofitting the entire fleet is a little bit unrealistic at this point, but we’re strongly considering spec’ing every new build with the system,” he said.

Retrofits are a key part of EnTrans’ strategy, too. It’s helping Marathon upgrade its tank trailers, and promoting aftermarket parts upfits with competitors, while working to extend its deal with Drōv, and move beyond petroleum trailers—where Radish said EnTrans still boasts its deepest build backlog—into dry bulk and stainless-steel trailers. “I envision installing [TankAI systems] on every unit we produce in the future,” Radish said. “At a minimum, it’ll be like the SiriusXM radio plan, where it’s installed on every trailer and comes with a one-year subscription, and you have the base model but can upgrade through the aftermarket or on trailers coming down the plant line.”

About the Author

Jason McDaniel

Jason McDaniel, based in the Houston TX area, has more than 20 years of experience as an award-winning journalist. He spent 15 writing and editing for daily newspapers, including the Houston Chronicle, and began covering the commercial vehicle industry in 2018. He was named editor of Bulk Transporter and Refrigerated Transporter magazines in July 2020.