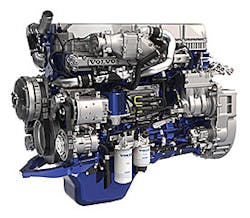

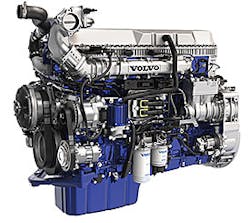

Volvo Trucks North America recently launched several new integrated powertrain solutions offering increased fuel efficiency, productivity, reliability, packaging, comfort, and uptime. The new offerings will be available in Volvo’s 2017 model trucks.

The new powertrain offerings include multiple engine enhancements, such as turbo compounding for the Volvo D13 engine; the introduction of Volvo I-Shift with Crawler Gears automated manual transmission; and a one-box Exhaust Aftertreatment System (EATS). The technology improvements deliver on Volvo’s commitment to drive integrated powertrain development to meet the various needs of customers in a full range of applications, bringing outstanding power, performance and efficiency.

“Volvo has long been a leader in offering integrated technologies that meet and exceed our customers’ expectations for fuel efficiency, power and performance,” said Gӧran Nyberg, president of Volvo Trucks North America. “These new Volvo powertrain enhancements incorporate our innovative engineering and technology expertise with our focus on meeting customers’ needs to offer them the best possible solutions for the best possible return on investment.”

For the first time in North America, Volvo’s 2017 D13 engine will be available with turbo compounding, a technology that recovers wasted exhaust heat and converts it to useable mechanical energy that is transferred back into the engine. The result of this recovered energy is up to a 6.5% improvement in fuel efficiency compared with previous engine models. Applications that benefit most from turbo compounding include long-haul, steady-state driving.

In another first, Volvo’s XE--eXceptional Efficiency--powertrain package with the D13 turbo compounding engine will be available to customers desiring to run in top gear in states and provinces that have 55 mph speed limits. Through downspeeding, XE allows the engine to cruise at up to 300 rpm less than the average truck sold today--significantly improving fuel efficiency. More than 27% of all Volvo models sold in 2015 featured an XE package, according to Volvo officials.

Volvo’s 2017 11-liter D11 engine and the 2017 D13 both received numerous updates designed to improve fuel efficiency. The updates include: a proven common-rail fuel system that reduces engine and cab noise, while optimizing fuel delivery; an available two-speed coolant pump that reduces parasitic loss; and redesigned pistons for greater combustion efficiency.

These improvements boost D11 to up to 425 horsepower, while improving fuel efficiency by up to 2.2%. The 2017 D13 reportedly will see up to a 2.5% improvement in fuel efficiency.

“Volvo I-Shift penetration reached a record 83% in 2015, demonstrating incredible progress from 2007 when Volvo was the first OEM to bring an integrated automated manual transmission to the North American market,” said Allison Athey, Volvo product marketing manager-transmissions. “Today, with hardware and software updates, as well as the introduction of the new version with crawler gears that have effectively doubled the overall ratio, Volvo is continuing its leadership in transmission technology.”

I-Shift with Crawler Gears will be available in two versions:

• 14 forward gears, including one low crawler gear (19.38 gear ratio) and one ultra-low crawler gear (32.04 gear ratio), which can operate down to 0.6 mph with 3.58 rear axle ratio

• 13 forward gears, including one low crawler gear (17.54 ratio).

Available as an overdrive in Volvo VHD, VNX, VNM, and VNL models, the I-Shift with Crawler Gears can be spec’d with Volvo D11, D13 and D16 engines.

All I-Shift automated transmissions received revised hardware for increased durability, including an upgraded countershaft for faster shifting and improved performance.

I-Shift efficiency received a boost from the Volvo I-See system, which works in tandem with the I-Shift transmission. Launched in North America by Volvo today, I-See is a new feature which learns the topography of the road, memorizes it, and stores it in the transmission for use the next time the driver travels the routes. The system stores up to 4,500 different hills.

The built-in electronics constantly monitor factors such as road grade, speed, weight and engine load to help maintain the most efficient gear possible. When the truck is operational, it automatically uses its knowledge to save fuel during the driving cycle. It optimizes gear shifting on rolling hills and hilly terrain. I-See handles hills efficiently by building speed before the hill, then curbs speed before the crest, Eco-Rolling down the hill and engine braking if necessary

“Rugged jobs require durable equipment that can stay ahead of the pace,” said John Moore, Volvo product marketing manager – powertrain. “The integration between the transmission and the engine is critical to getting the best performance and efficiency possible. Drivers are now going to get more power for less fuel spent.”

I-Shift is a key component to Volvo’s XE powertrain package. The inclusion of the new I-Shift with Crawler Gears in the XE Adaptive Gearing package expands the capabilities of XE from 80,000 pounds up to 110,000 pounds. GCW as the low gear ratios maintain startability and enhance slow speed performance on softer ground.

Volvo has introduced a new one-box exhaust aftertreatment system (EATS) that combines the diesel particulate filter (DPF) with the selective catalytic reduction (SCR) and diesel exhaust fluid doser into a single unit. The system also features a new copper-zeolite coating that improves low temperature NOx conversion for improved emissions.

The new design configuration results in better thermal performance for improved efficiency, smaller packaging requirements and an approximately 17-pound weight reduction compared with the two-box unit. This provides additional frame rail space for added packaging flexibility.

The new one-box EATS will be standard on the D11- and D13-equipped powertrains. The two-box solution will remain on the D16.

Vehicle uptime is a critical factor for drivers and fleet managers, which is why Volvo is dedicated to ensuring new technology helps maximize time on the road through Volvo Remote Diagnostics. Remote Diagnostics is a telematics-based proactive diagnostic and repair planning system that monitors critical engine and I-Shift fault codes.

When an issue is detected, the system identifies what parts will be needed and provides technicians with straightforward repair instructions--even before the truck arrives for service. Remote Diagnostics can reduce the diagnostic time by up to 70% and lower repair time by more than 20%.

Remote Diagnostics has been standard on all Volvo-powered models since 2013. Remote Diagnostics is a central component of Volvo’s uptime services, which also include 24/7 support, Volvo Action Service, and ASIST, Volvo’s service management platform.