OVER the past two years, the Alfa Laval Gamajet Sidewinder has steadily earned a place in the tank cleaning market. Sidewinder enables horizontal cleaning inside a cargo tank.

Hundreds of hours of engineering, design, testing, and retesting have perfected and proven the effectiveness of the Sidewinder system, according to Alfa Laval officials. The Sidewinder is an accessory that enables a Gamajet tank cleaning device to run on its side, effectively ensuring the water jets hit the cargo tank bulkheads with more frequency.

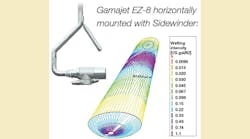

Instead of an elliptical spray pattern across the tank wall, the Sidewinder enables the machine to form a figure-8 pattern sweeping the length of the cargo tank. This increases the number of hits to the bulkhead by 30 times, cleaning the tanker in half the time. Coupled with an Alfa Laval Gamajet 8 Gamajet 4, which are desgned to easily handle 20- to 30-ft throw lengths, the Sidewinder system enable much faster cleaning of tank trailers and tankcars.

While a horizontally mounted cleaning machine experiences more wear, it is not excessive, according to Alfa Laval officials. Offseting factors of hydraulic load and reduced cycle time help compensate for the sideways mounting.

The Sidewinder system is designed just for Alfa Laval Gamajet cleaning machines, company officials said. The Gamajet 4 machine has a durable gear train to handle the stress. The Gamajet 8 also works well in the system because it offers a small diameter and a sealed gear train.

The gear ratios and spray coverage of these two devices are capable of covering the interior of a tank trailer in half the time of an upright machine. Perhaps most importantly, the horizontal spray pattern is twice as effective.

When a tank cleaning device is run in an upright position, it hits the floor below the manway with a violent blast that is just four feet off the surface. This violent impact is repeated every 30 seconds or less, and it is wasted cleaning impact.

With sideways mounting, the cleaning machine’s spray hits the difficult-to-clean tank heads every 30 seconds. The area directly below the manway is washed every three minutes with direct impact and is covered with the cleaning solution and wash water almost continually. As a result, cleaning times can be reduced by 30% to 50%. ♦